Rozwiązania HUBER dla przemysł mleczarski

Wastewater from the milk processing industry contains much fat and solids, and high COD and BOD freights. Heavy pollution surcharges must be paid for these freights.

Discharge requirements depend on the size of the business, its product range, wastewater flow and freights. While small businesses must only remove fat and solids, larger factories are usually also required to reduce their COD and BOD freights. Of course, discharge standards must be met; but in many cases it is cost-effective to do more and minimize wastewater and waste costs.

It is always economical to reduce the freights on site so that the wastewater can be discharged into municipal sewers with no or minimal surcharges. It is often cost-effective to treat the wastewater even further so that the effluent can be directly discharged into receiving waters.

Precondition for any customized solution is thorough investigation of the specific conditions.

Koncepcja systemu

Opis procesu

Opis procesu

Process Description

Wastewater from tanker truck washing places and delivery areas contains soil, sand and grit. It first flows through our HUBER Circular Grit Trap. The separated mineral-rich slurry is pumped to our HUBER Grit Washer wherein organic matter is separated from mineral particles. The clean and dewatered sand and grit is reusable as construction material.

Wastewater from milk processing contains organic solids, such as fruit pieces or grains (e.g. from yoghurt production), and debris, such as broken glass and packing materials. We remove these solids with a ROTAMAT® Rotary Drum Fine Screen, with i.e. a wedge wire spacing of 1mm or a perforated plate spacing of 2 mm.

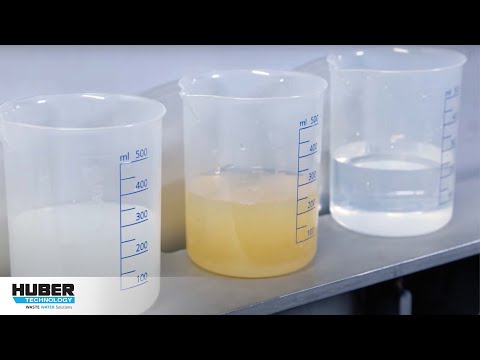

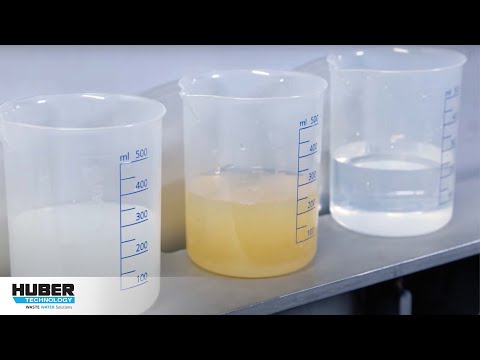

After intermediate storage for flow and freight equalization, we treat the combined wastewater flows in a HUBER Dissolved Air Flotation Plant (DAF). Depending on the requirements, the wastewater is first chemically conditioned (precipitated, coagulated, flocculated and/or neutralized) within a tubular reactor. The DAF effluent can be discharged into a municipal sewer. However, it still contains a considerable COD and BOD freight, mostly in form of dissolved lactose (milk sugar).

For full-biological treatment we provide a HUBER VRM® Membrane Bioreactor. Its permeate effluent can be directly discharged into receiving waters. The permeate effluent is of outstanding quality and virtually disinfected, also permitting its recycling as process water.

Waste activated sludge, consisting of the biomass generated by biological treatment, is concentrated in our ROTAMAT® Disc Thickener and then blended with already thickened flotate sludge from the DAF, consisting mainly of coagulated oil and fat. The blended sludge is then dewatered in our ROTAMAT® Screw Press. The dewatered sludge cake and the compacted screenings are preferable supplied to a biogas plant to increase its gas production.

When we implement our solutions, we also provide our well-proven HUBER stainless steel components, e.g. Screw Conveyors, Manhole Covers and Stairways, Platforms and Guardrails.